Manufacturers are dealing with more competition, more regulation, and more demanding customers. But the manufacturers that lead the pack have found that intelligent automation is giving them the agility and flexibility they need to thrive in a more crowded and competitive market.

Manufacturers were the early adopters of automation. You can’t picture a modern factory without the highly synchronized, highly precise movements of an army of robots. But there’s more to manufacturing success than what happens on the shop floor. There’s sourcing the right parts and materials. There’s anticipating customer demand. There’s processing orders. There’s orchestrating your supply chain and production network. There are partner and customer relationships to cultivate and manage. There are books to balance and compliance, sustainability aspirations to be met. And the processes that support those things are great candidates for automation.

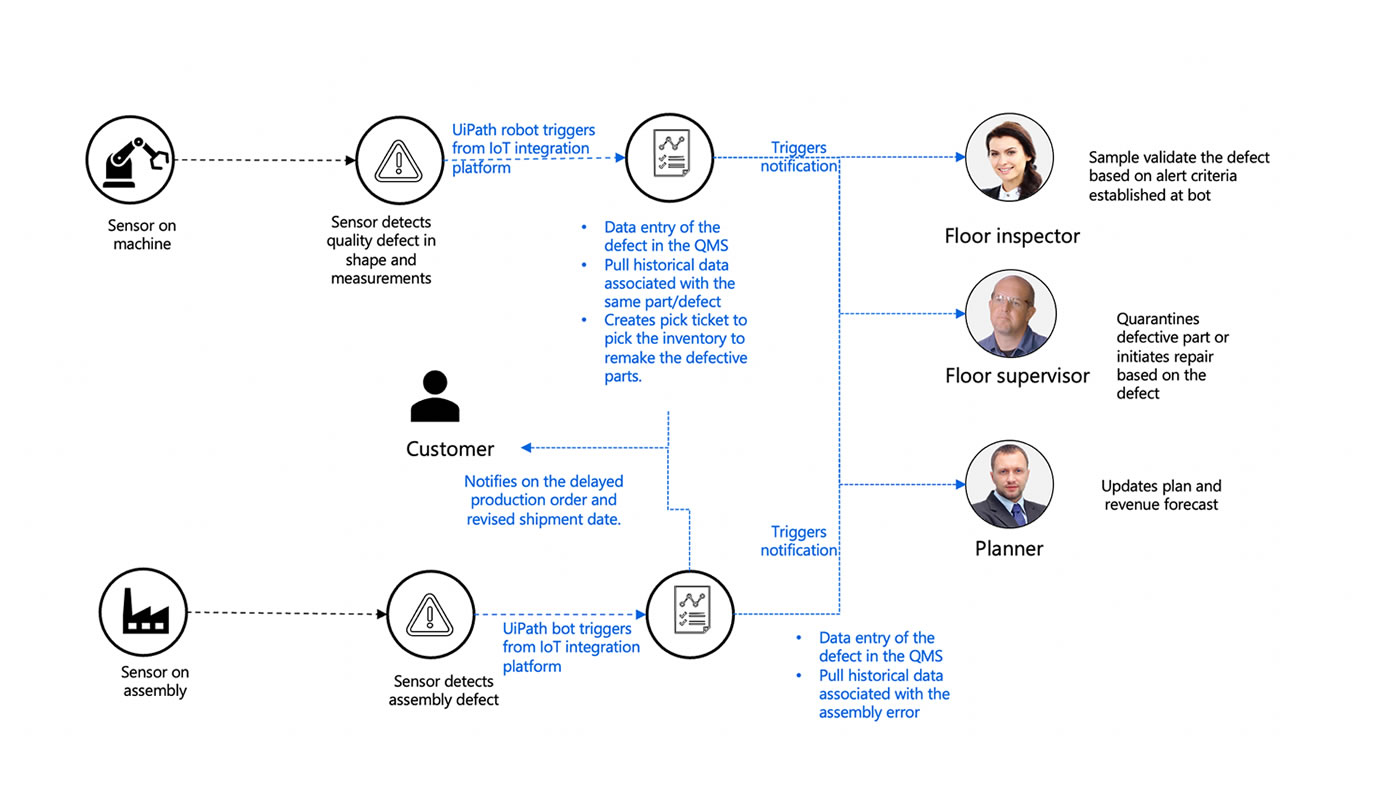

But many of the enterprise information (IT) and operational technology (OT) systems manufacturers rely on don’t easily interoperate and share data. That creates gaps in your manufacturing operations and processes that make it harder to identify and address inefficiencies across production networks and entire value chains. Automation can bridge those gaps. It can support smarter, faster, and more accurate processes—and reduce the administrative workload that can slow down manufacturing processes.

Automation can do more than help you build great products. It can also help you build a great business.